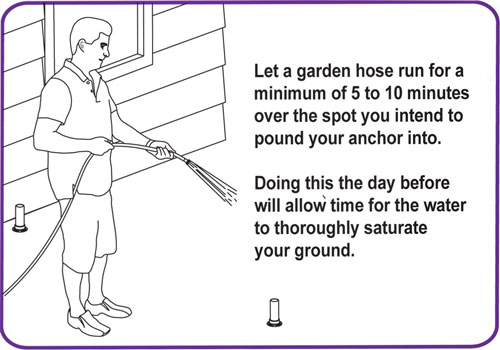

Your pipe anchors, even when driven to the recommended depths of 36 inches AND 48 inches, will have a wind load resistance problem if the ground around them is unstable. If your entire fence line is located in loose or extremely loamy conditions, you can install our fence system much like you would if you were installing a traditional fence with concrete footings. Unfortunately you did not purchase our fence to do that. You wanted to avoid drilling, digging, cementing etc. However, maybe in the course of installing your fence, you’ve run across a few occasional spots in your fence line that have shifty soil conditions. The following illustrations outline three options to overcome those isolated spots.

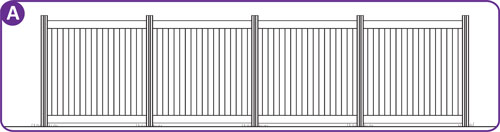

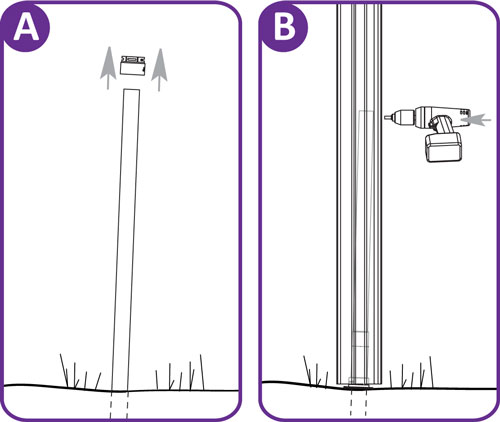

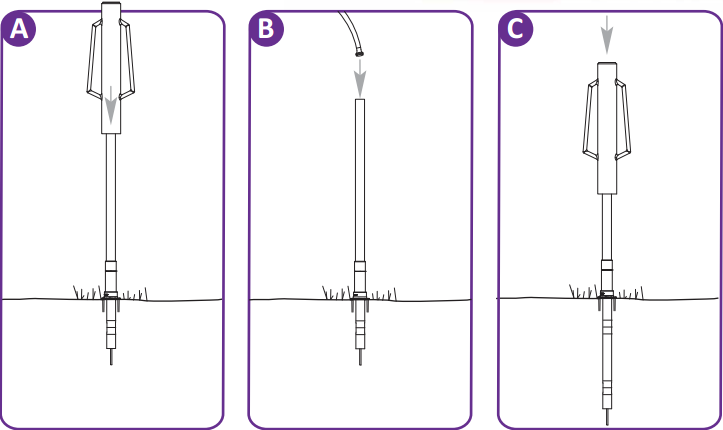

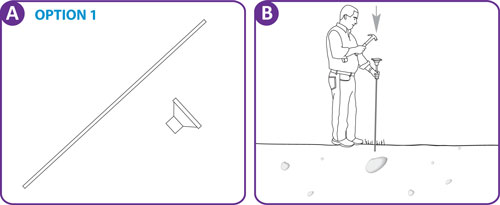

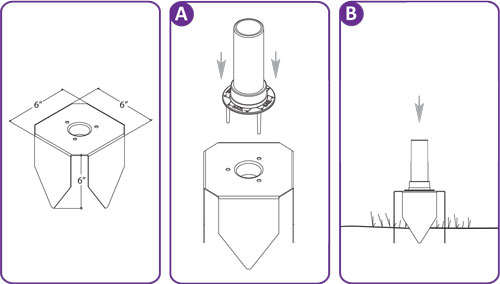

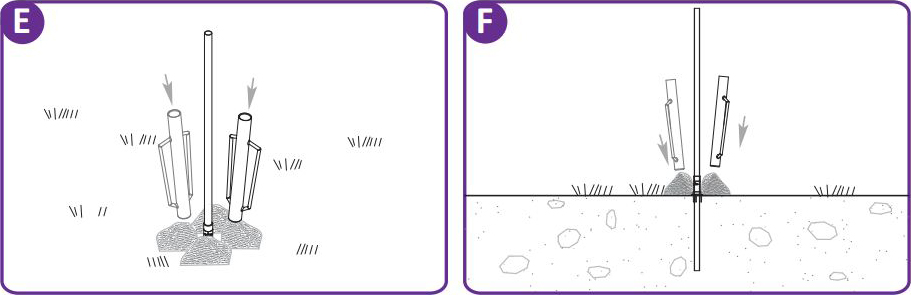

Option 1: Install Metal Post Stabilizers (purchase separately)

You can purchase our Metal Post Stabilizers here (click here for vinyl or click here for ornamental aluminum).

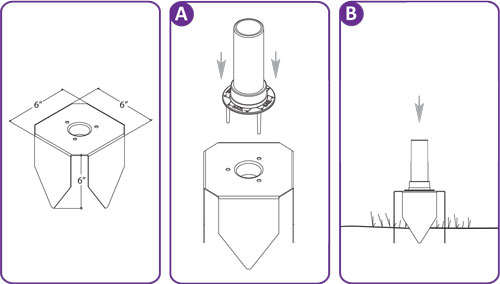

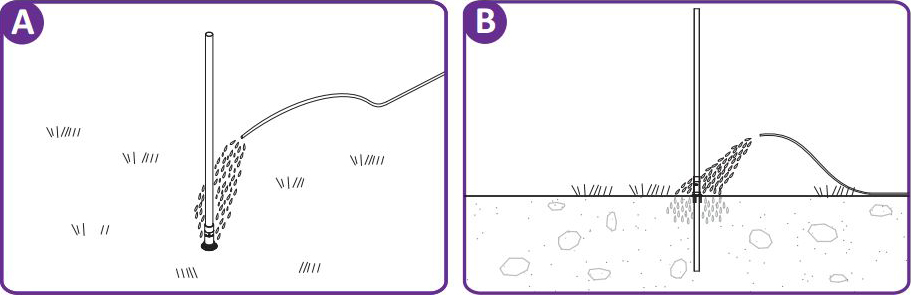

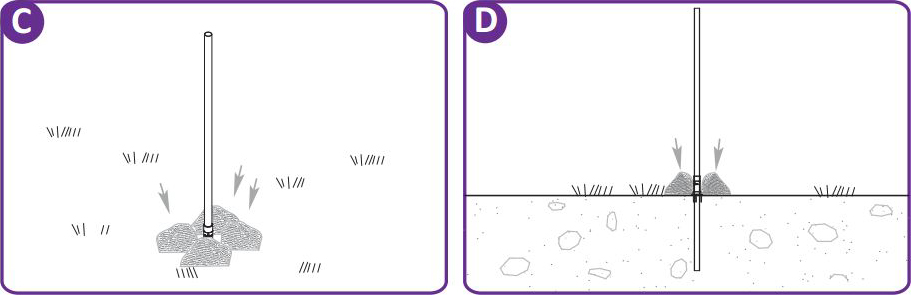

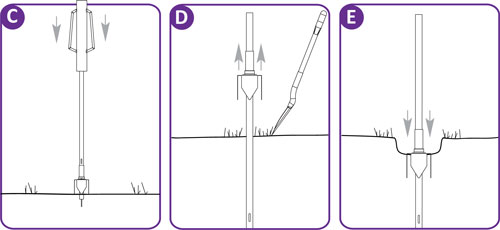

A. Insert the three legs on the Anchor Positioner into the three holes on the Metal Post Stabilizer.

B. Identify location and insert flush into the ground using hand force.

C. Once position is identified, insert your anchor and begin to pound into place.

D. Remove 1in. to 4in. of soil underneath the unit.

E. Ensure the entire unit is stomped tightly into the ground. Use hammer on exposed metal edges if required.

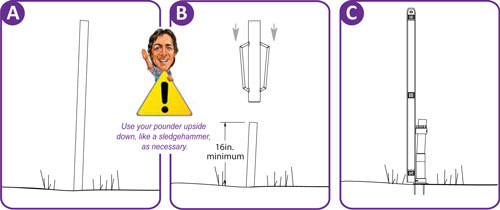

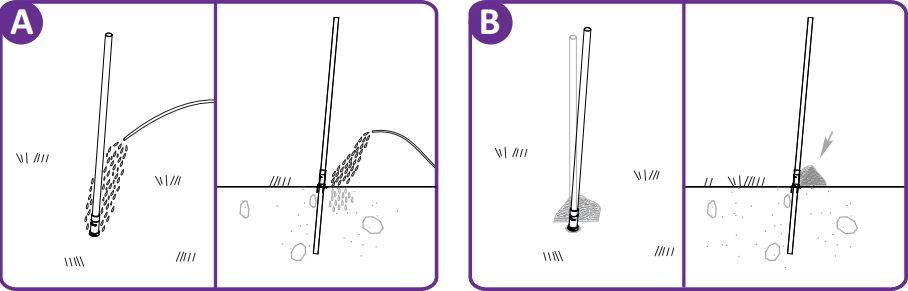

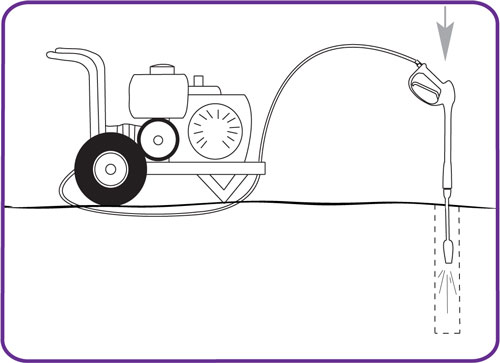

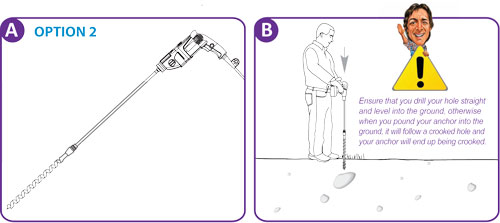

Option 2: Install a traditional concrete footing around your anchor

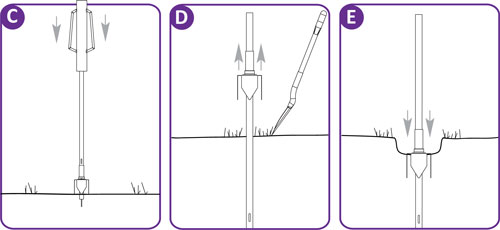

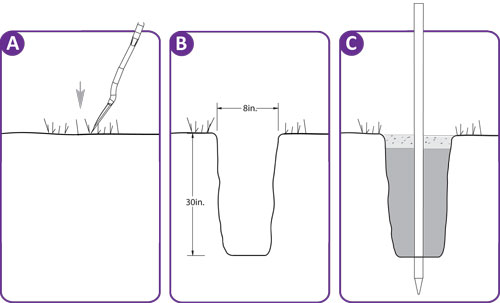

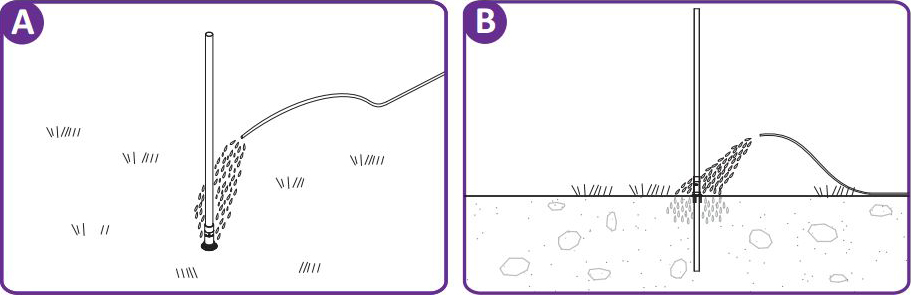

A, B. Dig hole 8in. in diameter by 30in. deep.

C. Pour 3 to 5 bags of pre-mixed concrete into the hole and install your anchor.

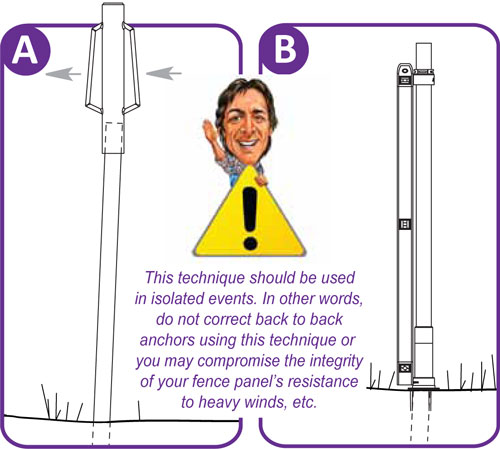

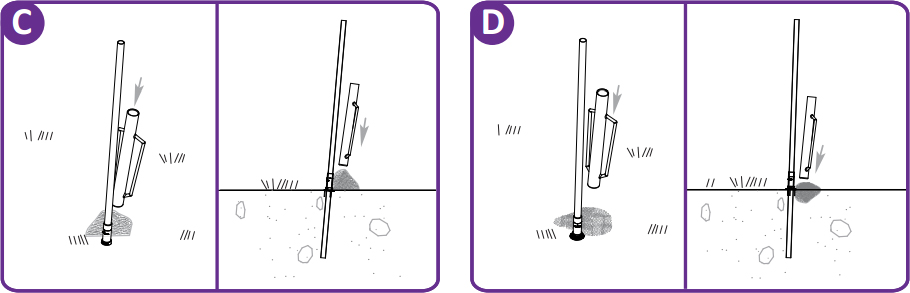

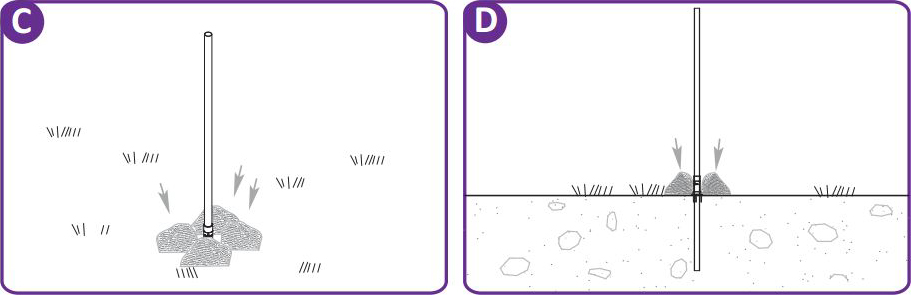

Option 3: Use Styrofoam filler around your anchor

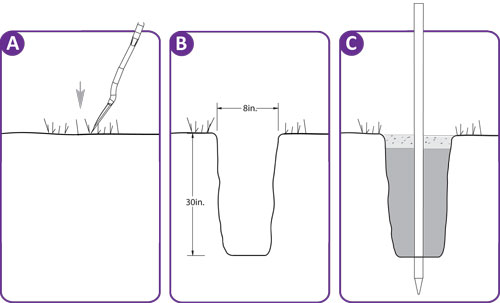

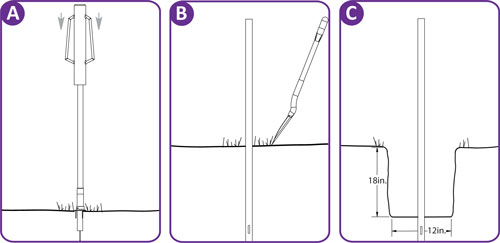

A. WamBam your anchor into the suggested depth, either 36in. or 48in. deep.

B, C. Remove anchor positioner and dig around the anchor a minimum of 18in. deep x 12in. square hole.

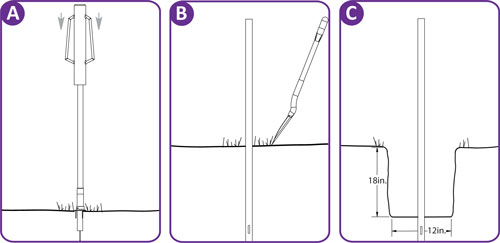

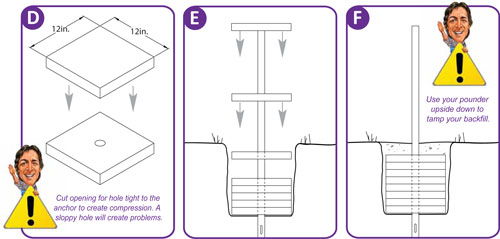

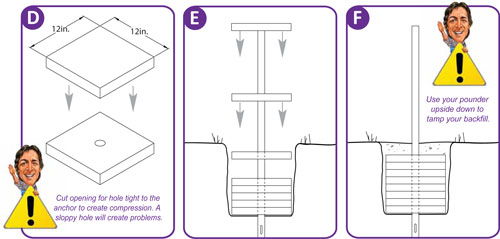

D. Cut 1 or 2in. Styrofoam into 12in. x 12in. square blocks and cut 1-5/8in. hole in the center.

E. Load Styrofoam blocks over the anchor down into the bottom of the hole.

F. Fill in the last 3in. or 4in. with back filled dirt.

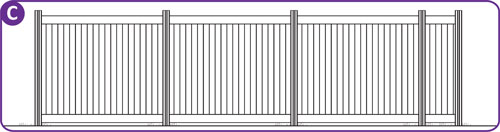

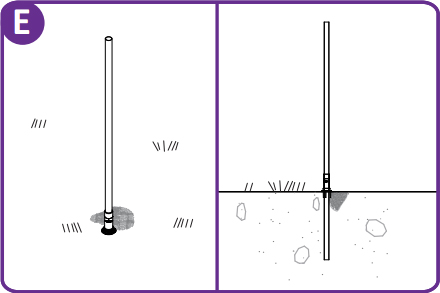

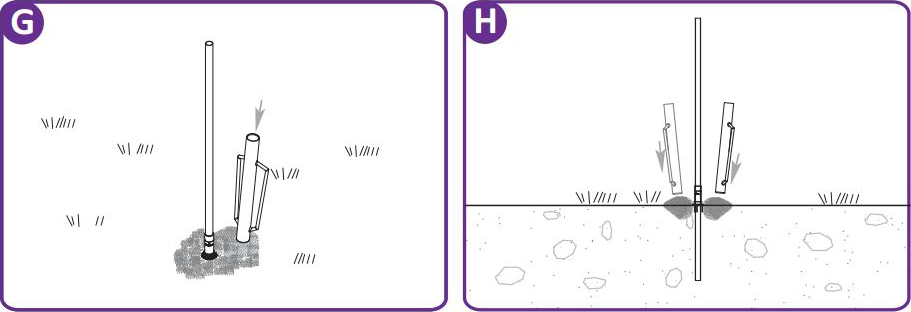

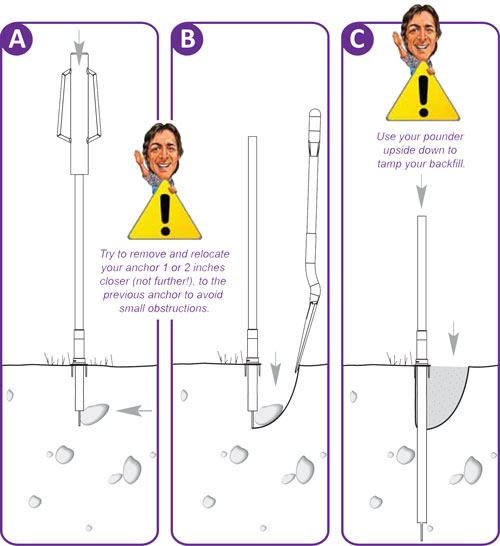

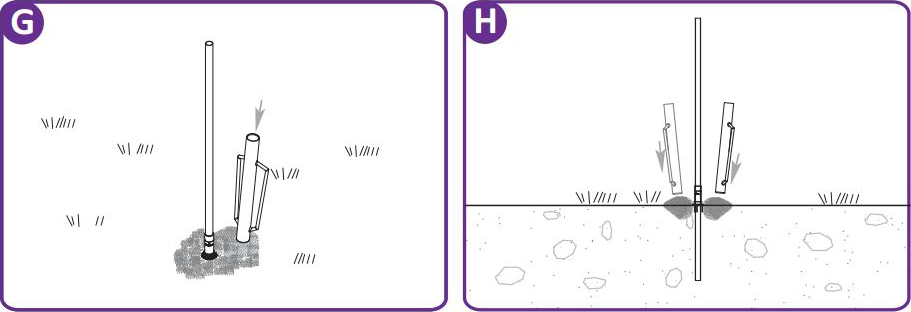

Option 4: Compact the Soil Around the Anchor

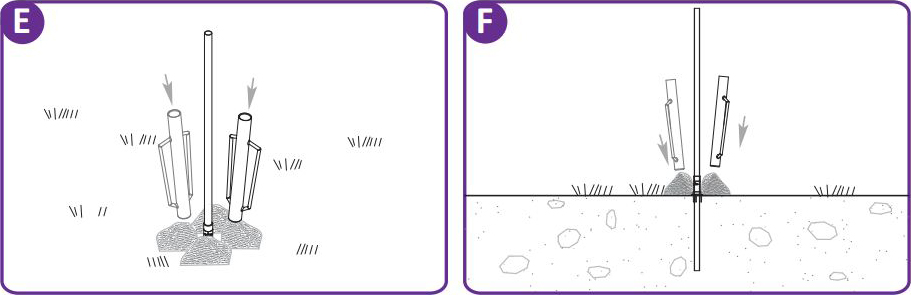

Ensure the ground around the anchor is moist to accelerate compaction

Add additional soil in a 10″ to 12″ diameter circle as necessary around the anchor.

Flip the post driver upside down to use as a compaction tool. A spud bar flipped upside down also works a great compaction tool.

Add additional soil and repeat as necessary. The intent is that the ground around your anchor should become very dense and well compacted.

! Note:

This can also be done after your fence is installed if necessary. Ideally, however, it should be done at the pipe anchor installation stage.

by Denise

by Denise